I-Wheat Corn Grain Ehambisa Ibhande Lokuthutha

Ubude bokudlulisa bokuhambisa ibhande lethu busukela ku-10m kuye ku-250m.Ijubane lebhande elitholakalayo ngu-0.8-4.5m/s.Njengomshini jikelele wokucubungula okusanhlamvu, lo mshini wokudlulisa usetshenziswe kabanzi embonini yokucubungula okusanhlamvu, imboni yamandla, amachweba kanye nezinye izikhathi zokudlulisa i-granule, impushana, i-lumpish noma izinto ezifakwe esikhwameni, njengokusanhlamvu, amalahle, imayini, njalonjalo.

Isakhiwo esiyinhloko kanye nesimiso sokusebenza

Amarola e-Rotor asekela ibhande eliyindandatho eligijima futhi lidlulisela izinhlobo ezihlukahlukene zezinto kulo ibanga elide.

Isici

1. Kokubili okokusebenza kanye nebhande kuhamba ngokuzinzile.Akukho ukuchezuka kwebhande noma ukuvuza kwezinto ezibonakalayo.

2. I-conveyor yebhande ingaba ngohlobo olungaguquki noma uhlobo lweselula, futhi ingafakwa ivundlile noma nge-engeli ekhonjiwe.

3. Izinto ezisetshenziswayo zishayelwa amarola anenjini noma amagiya amamotho.

4. Le sistimu yokuthutha iza nomklamo olula, umsindo ophansi wokusebenza, futhi kulula ukuyinakekela.

5. Ububanzi obuzikhethela bokugoqa bejubane lebhande (0.8m/s~4.5m/s), Isivinini esikhulu kanye nomthamo omkhulu webhande kuholela ekusebenzeni kahle okuphezulu komthumeli wethu webhande.

6. Ngazo zonke izinhlobo ze-granular, impushana, izinto ze-lumpish, nezinto ezifakwe izikhwama.

Uhlu Lwezinhlaka Zobuchwepheshe

| Uhlobo | Amandla | Isivinini Somugqa | Ububanzi | Amandla |

| I-TPDS50 | 80-100 | 1-3 | 500 | Kuya nge |

| I-TPDS65 | 165-200 | 1-3 | 650 | |

| I-TPDS80 | 240-300 | 1-3 | 800 | |

| I-TPDS100 | 400-500 | 1-3 | 1000 | |

| I-TPDS120 | 580-700 | 1-3 | 1200 | |

| I-TPDS140 | 750-900 | 1-3 | 1400 |

Imininingwane Yomkhiqizo

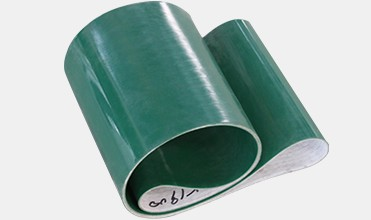

Ibhande le-Rubber conveyor:

ukwamukela indwangu kakotini noma indwangu yendwangu ye-fiber yamakhemikhali ukwenza ungqimba oluyisisekelo, olunoqweqwe lwepulasitiki olungagqoki lwekhwalithi ephezulu;lolu hlobo lwebhande le-rubber conveyor liyanwebeka futhi liyavumelana nezimo.

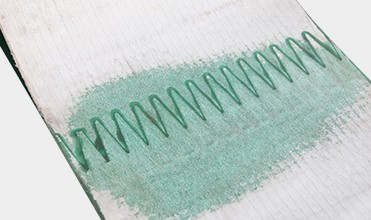

Ukushisela imfoloko yebhande:

Ikhwalithi yejoyinti ithinta ngqo amandla onke ebhande lokudlulisa.I-fork jointing welding inamandla amakhulu, ingavimbela ukugqwala okuyisisekelo ukuze kube nempilo ende yesevisi.Ijoyinti libushelelezi futhi alinasikhawu, ibhande lokudlulisa lihamba kahle ngaphandle komthelela, futhi linamandla amahle okuguquguquka kanye nekhono lomkhombe.

Irola emise okwesigubhu:

ngerola eliphakanyiswe maphakathi lingavimba ngempumelelo ukuchezuka kwebhande lokudlulisa.

Idivayisi ecindezelayo:

Ukuqinisekisa ukushuba okwanele, ukugwema ukushibilika kwebhande le-conveyor ku-roller yokushayela kanye nokuwohloka ngokweqile.

I-Idler roller:

idivayisi esekelayo yokudlulisa ibhande, ayinakulungiswa, ukugxuma okuncane, ukujikeleza okushelelayo, impilo ende yesevisi.Izinhlobo ezahlukahlukene zezihlalo ezithwele kanye nesakhiwo sokuvala ukuze kukhethwe umsebenzisi, uphawu lweLabyrinth oluneziteshi eziningi lungavimbela uthuli nokucwiliswa emanzini.High-density steel ipayipi isetshenziswa ukuqinisekisa roller vibration ongaphakeme kanye nomsindo ongaphakeme.

Mayelana NATHI

Izinkonzo Zethu

Izinsizakalo zethu ezivela ekubonisaneni ngezidingo, idizayini yezixazululo, ukukhiqizwa kwemishini, ukufakwa endaweni, ukuqeqeshwa kwabasebenzi, ukukhanda nokunakekelwa, kanye nokunwetshwa kwebhizinisi.

Siqhubeka sithuthukisa futhi sibuyekeza ubuchwepheshe bethu ukuze buhlangabezane nazo zonke izimfuno zamakhasimende.Uma unemibuzo noma izinkinga mayelana nensimu yokugaya ufulawa, noma uhlela ukumisa izitshalo zokugaya ufulawa, sicela ukhululeke ukuxhumana nathi.Sithemba ngobuqotho ukuzwa kuwe.

Umgomo Wethu

Nikeza Imikhiqizo Enhle Nezisombululo Zokukhulisa Izinzuzo Zamakhasimende.

Izimiso Zethu

Ikhasimende Okokuqala, Liqondiswe Ubuqotho, Ukuqamba Okusha Okuqhubekayo, Lwela Ukuphelela.

Isiko Lethu

Vula futhi Uhlanganyele, Win-win Ukubambisana, Ukubekezela kanye Nokukhula.