Ukunemba kokulinganisa kungafinyelela ku-0.5% -3%, ukusabela okubucayi, nokuzinza kwesikhathi eside sokusebenza

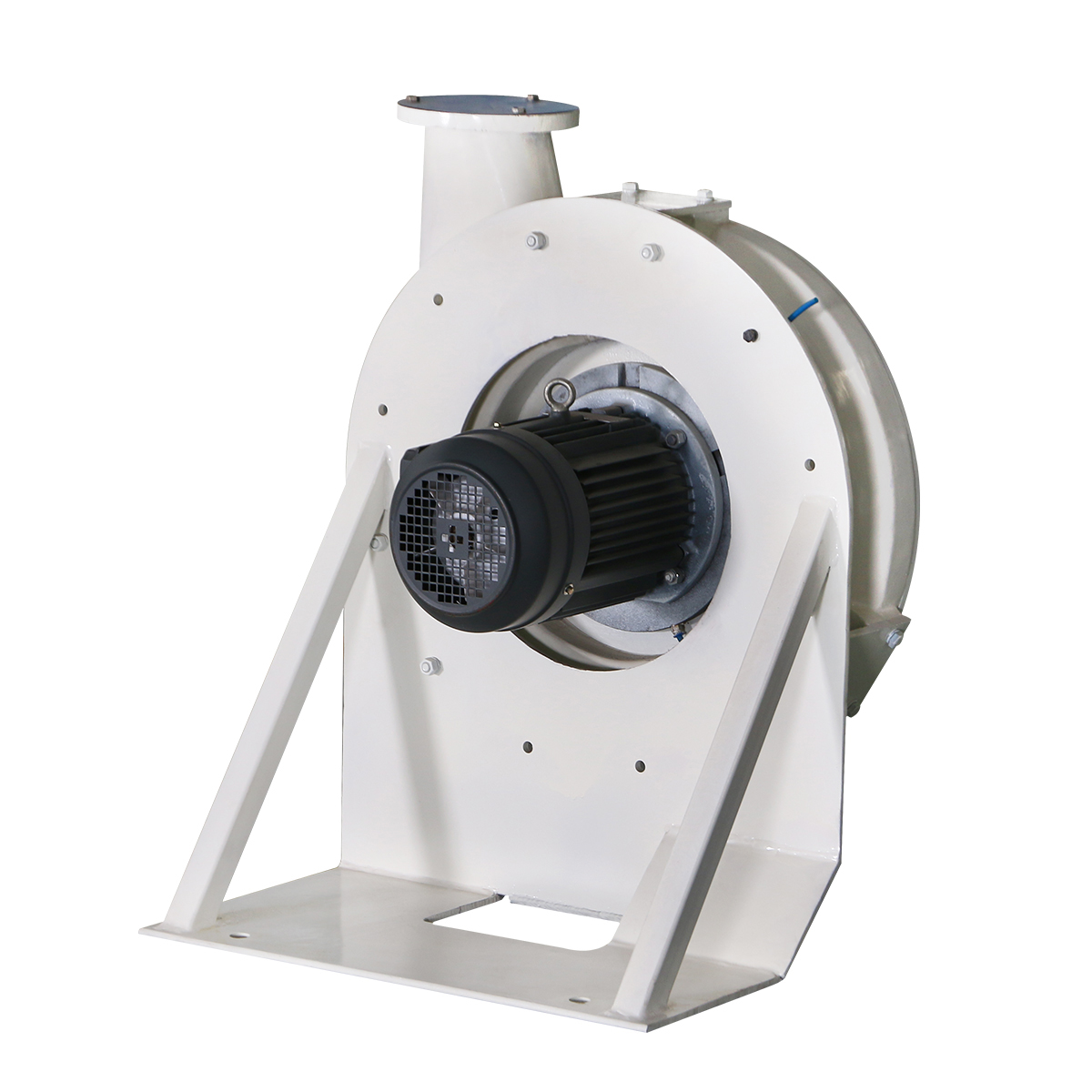

Umshini Wokulinganisa Kakolweni

Isicelo

Isilinganisi sokugeleza sinikeza ukulawula ukugeleza okuqhubekayo noma ukuhlanganisa okuqhubekayo kokuqinile kwenqwaba egelezayo.Ifanele izinto eziningi ezinobukhulu bezinhlayiyana ezifanayo kanye nokugeleza okuhle.Izinto ezijwayelekile yimalt, irayisi nokolweni.Ingasetshenziswa njengengxube yokusanhlamvu ezigayweni zikafulawa nasezigayweni zerayisi.

Isistimu ye-batching eku-inthanethi

I-Flow balancer: Ukwamukela inzwa yokucindezela kanye nobuchwepheshe be-chip eyodwa, inomgomo ofanayo wokusebenza noBuhler, umehluko ukuthi i-actuator ye-Buhler ithatha isango lokulawula isilinda, kodwa sisebenzisa i-gear saving gear motor (≤40W) ukulawula isango lesilayidi, okungagcini nje ukuthuthukisa kakhulu ukunemba kwesilinganiso sikakolweni futhi kulondoloze amandla amaningi, kodwa futhi kungathinteki ukushisa ebusika.

I-Flow balancer iyisistimu yokulawula iluphu evaliwe ezimele, futhi uchungechunge lwe-flow balancer lwakha uhlelo lwe-on-line lwesilinganiso sikakolweni.

Uhlelo lwesilinganiso sikakolweni lungalawulwa ngokuzenzakalelayo futhi lulungiswe ngokuya ngenani eliphelele kanye nengxenye enqunywe amaklayenti, futhi imingcele yesistimu ingashintshwa ngokungahleliwe.Uhlelo lungabuye luxhunywe nomshini we-PC ophezulu wamakhasimende, ngakho-ke, ikhompuyutha ingalawula futhi iphrinte amafomu ombiko.

Asikho isikhala esiyimpumputhe semishini ku-balancer yokugeleza;futhi impahla igeleza ngamandla adonsela phansi, okuqinisekisa ubuqotho bezinto zokukala.

Izici

1)Control and balance materials flow.

2) Qinisekisa ubuqotho bezinto zokwakha.

3) Amapharamitha wokugeleza angasethwa ngokuya ngezidingo.

4) Ukugeleza okunqwabelanayo, ukugeleza okusheshayo nokugeleza kokusetha kungaboniswa.

5) Ukunemba okuphezulu nokuvumelana nezimo okuqinile.

6) I-alamu ezenzakalelayo.

7) Ukuvikelwa kwedatha okuzenzakalelayo lapho amandla ehluleka.

8) Isixhumanisi esibonakalayo sokuxhumana esijwayelekile se-RS-485

Uhlu Lwepharamitha Yezobuchwepheshe:

| Uhlobo | Ububanzi(mm) | Amandla(t/h) | Ukunemba(%) | Ukusetshenziswa Komoya(L/h) | Usayizi Womumo LxWxH(mm) |

| I-HMF-22 | Ø120 | 1~12 | ±1 | 150 | 630x488x563 |

Ingavala ngokushesha isango lezinto ezibonakalayo uma kwenzeka licisha noma lingasebenzi ugesi, futhi ivimbele ukuvimba okokusebenza komfula .

Ngesistimu yokulawula ye-elekthronikhi, isilawuli sesikhathi sangempela esikude singabonakala kalula, futhi isilawuli sokukhiya ngempahla engezansi singenziwa.Uhlelo lunomsebenzi we-alamu uma izinto zincane noma umshini unephutha.